A monoblock refrigeration unit is one of the most efficient and practical solutions for walk-in coolers and walk-in freezers, especially…

Specification

- Core material: PU(Polyurethane);

- Surface material: galvanized color steel/304 stainless steel

- kick plate on the door: anti-slip stainless steel/anti-slip aluminum

- frame:aluminum sheet

- thickness: 75mm/100mm/120mm/150mm/200mm

- PU density: 40±2kg/m³

- door opening size: can be customized.

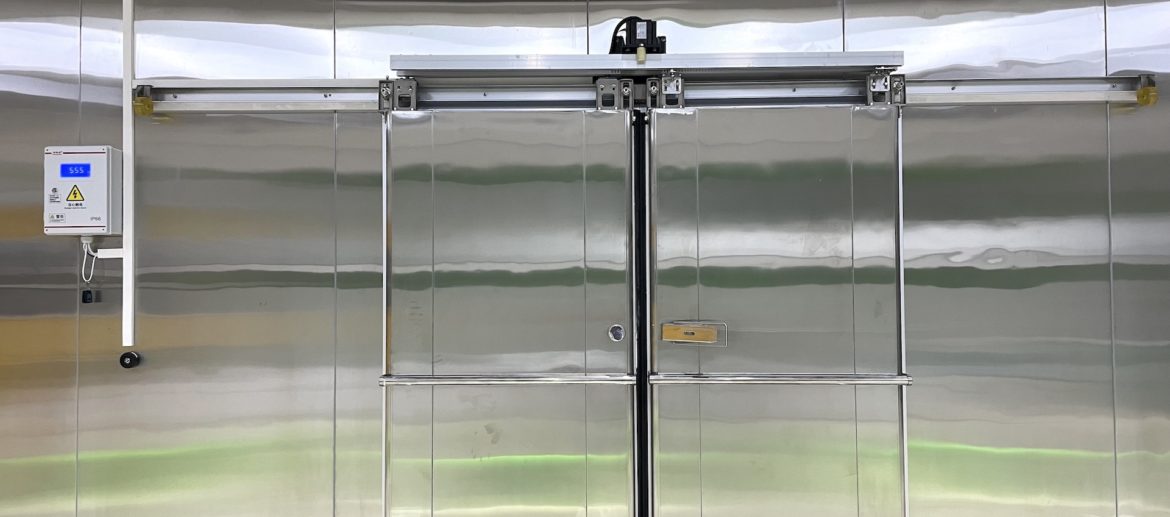

Sliding door: manual or automatic

Research & Development

In the cold storage industry, sliding doors have evolved to incorporate advanced insulation materials, air-tight sealing technologies, and automated operation systems. Modern sliding doors now feature high-density polyurethane foam cores, heated sealing edges to prevent ice buildup, and motion sensors for hands-free operation, enhancing both efficiency and energy savings.

With continuous technological advancements, sliding doors are becoming more durable, thermally efficient, and customizable, ensuring better performance for industries that rely on precise temperature control, such as food storage, pharmaceuticals, and logistics.

Latest From Blog

NSF Certified Cold Room Solutions for the U.S. and Canada

As food safety regulations become increasingly strict in the United States and Canada, NSF certification has become a key requirement…